Lubrication Engineers' Xpert™ Benchmark Audit Service

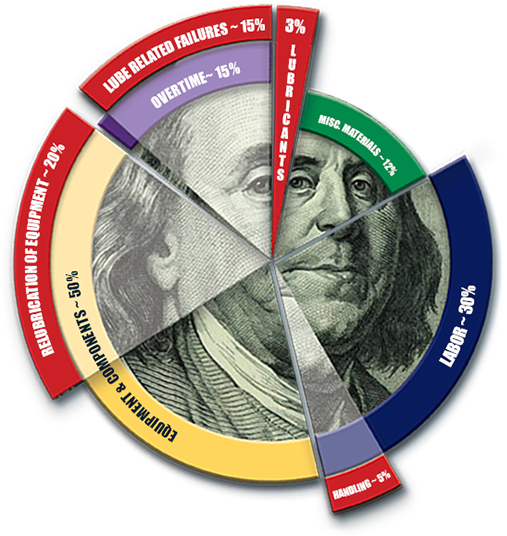

Those who have any awareness of the benefits of having a Lubrication Management Program understand there are multiple areas and opportunities for improvement in virtually any facility that uses lubricants. Low hanging fruit abounds with opportunities for meaningful advancement that goes right to the bottom line. Asset managers understand that attaining optimum reliability requires an all-in commitment and dedication to the cause. Like anything else, this concept generally needs to be sold to management. Simply asking if you can get consent to improve your lubrication program will generally result in question: what’s it going to cost and what benefits will be realized? That then goes to what’s wrong with the program we have now?

Those who have any awareness of the benefits of having a Lubrication Management Program understand there are multiple areas and opportunities for improvement in virtually any facility that uses lubricants. Low hanging fruit abounds with opportunities for meaningful advancement that goes right to the bottom line. Asset managers understand that attaining optimum reliability requires an all-in commitment and dedication to the cause. Like anything else, this concept generally needs to be sold to management. Simply asking if you can get consent to improve your lubrication program will generally result in question: what’s it going to cost and what benefits will be realized? That then goes to what’s wrong with the program we have now?

This is where LE’s Xpert™ Benchmark Audit provides huge value.

As per the famous quote by Peter Drucker: “If you can’t measure it, you can’t improve it.”

Our audit assesses your organization on 9 categories and provides a scoresheet enabling you and your team to see exactly where improvement can be made as well as where you are doing well. You then have a roadmap that paves the way towards a World Class Lubrication Management Program. The icing is that you have the opportunity to work with a company dedicated to helping you succeed. Results are: reduced lubricant consumption; reduced manpower requirements to maintain equipment; enhanced safety, higher levels of machine reliability and increased profits.

ONSITE LUBRICATION SURVEYS

Our world class lubrication reliability program provides measurable results for those who think in terms of total cost of equipment ownership. Our Lubrication Technical Consultants will partner with you to assess every lubricated component in your plant or fleet to measure current results and identify areas that are costing you time and money. Whether you choose to survey the entire operation or just focus on a few areas, you'll be able to compare the before to the after. To take the guesswork out your lubrication budget, invite an onsite survey to document:

-

Equipment and Lube Room condition to identify factors impacting performance such as the presence of obvious contaminants like rust, dirt, varnish and/or sludge in components, past and current service intervals, a history of frequent or repetitive repairs and identification of root cause and/or a reduction in the quality of machine output

-

Review of OEM standards pertaining to the type of lubricants in use, whether filtration products are used or required, the number of lube points on each asset and the frequency and method of recommended maintenance procedures

-

Analysis of used fluid samples to determine the presence (and source) of contaminants; to determine the remaining useful life of the base lubricant and to measure depletion of anti-wear additives

-

Interpretation of all results to identify less obvious performance factors

LUBRICATION MANAGEMENT PROGRAM DESIGN & IMPLEMENTATION

Xpert ™ Program Design and Installation: All Systems Go

Using the metrics identified in the survey phase and considering the lubricant requirements necessary to increase equipment reliability and reduce downtime, our team will work with you to design and carry out a clear, concise, cost-effective Lubrication Management Program by:

- Providing performance-based recommendations on the most efficient lubricants and application methods for each asset including calculations of proper lube frequencies and amounts while considering OEM specifications, lubricant properties required in specific operating environments, consolidation possibilities and overall cost of usage

-

Expert consultation in the recommendation of equipment modifications and additions necessary to accomplish program maintenance goals including ongoing condition monitoring tools such as oil sampling and analysis and site glasses for key assets, automatic lubrication including single-point and centralized systems, filtration products such as portable filtration carts and desiccant breathers and lube room upgrades like state of the art storage and dispensing systems with color-coded identification systems.

Once decisions have been made regarding those recommendations, Lubrication Technologies Consultants can help design, install and service the systems selected with the objective of controlling contaminants, increasing equipment reliability and reducing costs, including systems in these key areas:

Once decisions have been made regarding those recommendations, Lubrication Technologies Consultants can help design, install and service the systems selected with the objective of controlling contaminants, increasing equipment reliability and reducing costs, including systems in these key areas:

-

Manual and automatic dispensing and online filtration systems to deliver optimum amounts of contaminant-free lubricant at cost effective intervals. Offering design and Installation of both oil and grease dispensing systems, we are familiar with the benefits these products provide with regard to increased personnel safety, enhanced machine reliability and increased productivity.

-

Storage and handling systems to reduce contamination, eliminate human error and minimize labor required for lubricant related tasks, prevent waste and reduce disposal costs

Condition monitoring systems to ensure that goals are met, not just at implementation but for years to come

Provision of ongoing technical consult on maintenance plans as improved technologies and new products become available.

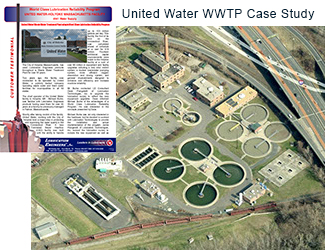

Click on the Case Study at above-right to view the Lubrication Reliability Program implemented at United Water in Holyoke MA by Lubrication Technologies, Inc.

Training and Resources

PERSONNEL EDUCATION & TRAINING FOR LUBRICATION MANAGEMENT BEST PRACTICES

Xpert ™ MLT Training is the First Step Towards Achieving Higher Levels of Equipment Reliability

Companies that strive for a world class equipment reliability program take a critical step in that direction by educating personnel responsible for maintaining critical assets. We believe that Machinery Lubrication Technician Level I Training and Certification is a critical first step toward achieving higher levels of equipment reliability.

There are multiple avenues toward that certification and one is easily available through Lubrication Engineers regularly scheduled training seminars held at LE Headquarters in Witchita Kansas. Lead by LE's expert instructor, Ken Kizer, CLS, OMA I & II, MLT I & II Instructor, Lubrication Training & Consulting, the Xpert MLT I course content includes:

- Lubrication Fundamentals

- Lubrication of Key Equipment Components

- Contamination Control & Storage and Handling

- Oil Analysis for Enhanced Equipment Reliability

- Lubricant Programs & Application of Lubricants

Send your lubrication technician, PM technician, millwright, and mechanical personnel for

MLT I certification and advance the lubrication knowledge and expertise of your whole team.

Gain control over the lubrication process and increase profits by increasing efficiency, reducing labor and downtime and protecting your assets.

If your looking for a customized educational seminar focusing on your industry and using your equipment,

give us a call today (413) 788-5823

Take a Customized Approach to Training Your Personnel

If your looking to avoid the costs of travel or just prefer a customized educational seminar focusing on your industry and using your equipment, then on-site training by our own resident expert will tailor a seminar at a time and location convenient to you.

David Piangerelli, STLE Certified Lubrication Specialist, ICML, MLT II, is a dynamic speaker with an in-depth grasp of all things lubrication and 46 years in the business of reliability improvements. He will customize training to meet the specific needs of your employees from basic concepts to hands-on workshops focusing on a specific asset.

(MLT I) Xpert ™ Machinery Lubrication Technician Level I Training & Certification

MLT I Training

Take Advantage of Upcoming Training and Certification Opportunities at LE's Centrally Located Facility in Wichita, KS

Common job titles for the individual who would become Level I MLT certified include lubrication technician, PM technician, millwright, mechanic, etc. Typically, this individual has regular contact with machinery and has routine influence over the condition of lubricants and hydraulic fluids in use. The individual is likely to be directly involved in the machine lubrication process.

Benefits - Xpert™ MLT I

• Advance the lubrication knowledge and expertise of your reliability team

• Gain control over the lubrication process and over your daily equipment reliability routine

• Increase profits by increasing efficiency and reducing labor and downtime, all while protecting machinery

Course Content

• Lubrication fundamentals

• Lubrication of key equipment components

• Contamination control & storage and handling

• Oil analysis for enhanced equipment reliability

• Lubricant programs & application of lubricants

Daily Schedule — Xpert™ MLT I

• Total number of days needed: 3½

• Days 1-3 training seminar (8 a.m.-5 p.m.)

• Day 4 optional ICML test from 8 a.m.-noon

Cost — Xpert™ MLT I

• See registration page or flyer on this page for current class pricing.

• Cost includes 3-day training seminar plus continental breakfast, lunch & beverages

• Optional ICML exam on morning of the third day is not included in class fee paid to LE. This registration step is separate and handled directly through ICML.

(CLS) Xpert ™ Certified Lubrication Specialist (CLS) Training & Certification

CLS Training

Take Advantage of Upcoming Training and Certification Opportunities at LE's Centrally Located Facility in Wichita, KS

Common job titles for individuals who would become CLS certified include equipment operators, lubrication technicians & engineers, maintenance managers & supervisors, reliability engineers, operations managers, predictive maintenance technicians, manufacturing and industrial engineers, oil analysis personnel, and lubricant consultants. Typically, these individuals are directly involved in machinery lubrication or oil analysis, or play a role in recommending, selecting or using lubricants.

Benefits - Xpert ™ CLS Training and Certification

Certified Lubrication Specialist (CLS) is the only independent certification for the lubrication professional that verifies your broad lubrication engineering knowledge. Certification recognizes those individuals who possess current knowledge of lubrication fundamentals and best practices in lubrication and maintenance in industrial settings. Certified individuals must have at least three years of experience in the field of lubrication.

Course Content Xpert ™ CLS

• Fluid power

• Bearings

• Seals

• Problem solving

• Lubricant manufacturing

• Solvents & cleaners

• Fluid condition

• Monitoring & reducing consumption

• Pneumatics

• Metalworking

• Lube analysis

• Transportation

• Storage, handling & application

• Gears

• Lube fundamentals

• Lubrication programs

Daily Schedule — Xpert ™ CLS

• Total number of days needed: 4½

• Days 1-4 training seminar (8 a.m.- 5 p.m.)

• Day 5 optional ICML test from 8 a.m.- noon

Cost — Xpert ™ CLS

• See registration page or flyer on this page for current class pricing.

• Cost includes 4-day training seminar plus continental breakfast, beverages & lunch

• Optional STLE exam on morning of fifth day is not included in class fee paid to LE. This registration step is separate and handled directly through STLE.

Click to Learn More...

![]()

An effective precision lubrication management program relies on Reliability-Centered Maintenance or RCM, a process to ensure that critical assets function at peak performance regardless of the harsh environmental conditions in which they run.

An effective precision lubrication management program relies on Reliability-Centered Maintenance or RCM, a process to ensure that critical assets function at peak performance regardless of the harsh environmental conditions in which they run.