- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

Condition Monitoring

Premium Lubricants For Reliability-Centered Maintenance Savings

Proper lubrication of machinery is the single most significant contributor to the long, problem free life of your machinery. It is estimated that 75% of all bearing failures are due to lubrication issues. Whether these failures are caused by contamination or just the wrong lubricant, the value of proper lubrication cannot be overstated.

Proper lubrication of machinery is the single most significant contributor to the long, problem free life of your machinery. It is estimated that 75% of all bearing failures are due to lubrication issues. Whether these failures are caused by contamination or just the wrong lubricant, the value of proper lubrication cannot be overstated.

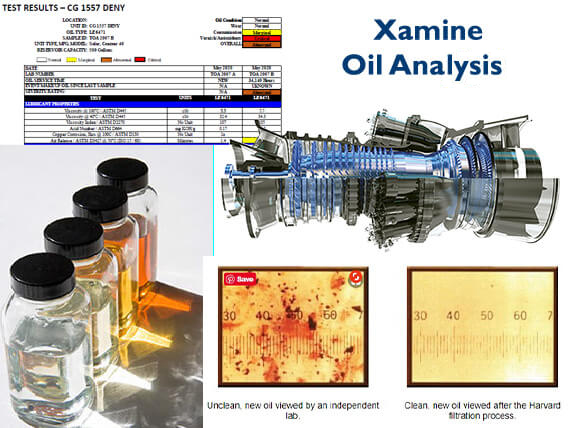

You cannot manage what you don't measure. Contamination, fuel dilution, additive depletion, viscosity and high wear counts all affect the performance and longevity of your equipment. We offer expertise and tools to help you set goals, ensure the use of the correct monitoring tools for your application and accurate interpretation of results for maximum ROI.

All lubricants are a combination of base oil and multiple chemical additives designed to eliminate, minimize or delay the negative effects of contaminants on the base oil. As the oil functions inside your assets, the additives that protect the base oil are depleted over time, sacrificed to the continued life of the molecular structure of that base oil. Once the additives have been depleted beyond their function, contaminants will begin to compromise the stability of the base oil. The depletion of additives may be accelerated under high operating temperatures, exposure to moisture and/or particulates. Left unchecked, the degradation of that base oil will compromise it's performance in the equipment, resulting in under-performance and, ultimately, costly equipment failure.

Monitoring the condition of the fluids that protect your equipment is the cornerstone a a world class reliability-centered maintenance program.

Analysis of lubricating oil, greases and hydraulic fluids gives a fast and accurate picture of what is happening inside power generators, gearboxes, compressors, hydraulic systems and other critical machines. It also yields vital information on the condition of the oil itself. Effective monitoring of lube oil allows maintenance to be scheduled efficiently, minimizing the risk of damage to expensive plants and avoiding unscheduled downtime.

PREDICTING MACHINE FAILURE WITH CONDITION MONITORING

Real Experiences in Reliability-Centered Maintenance Savings

Lubrication Technologies provides solutions for all lubricant conditioning monitoring. As an integral part of a World Class Lubrication Reliability Program, we help our customers increase operational efficiency while reducing the costs associated with lubricant contamination, misapplication and waste.

It's been widely reported that 80% (or more!) of wear and tear on your expensive machinery is due entirely to the presence of microscopic particulates in the lubricants that enable operation. And the damage, once done, is irreversible.

These microscopic particulates can be as small as 0.0001 micron (one example is smog) and range up to 10,000 microns (examples include rain, gravel and beach sand).

The human eye is capable of seeing only those particulates over 10-20 microns in size and when you consider that a human hair is difficult to see at 40 - 100 microns in size, you're left to conclude that there is a lot of damage going on that you cannot even see with the naked eye.

In fact, compare the size of those microscopic particulates with the clearances between the components in the servo valves, bearings, vane pumps and gear pumps. If a mere 0.5 to 5 micron clearance exists for the lubricant film thickness to protect those components from wear and tear, then even the smallest of microscopic particulates becomes an obvious threat to the performance of your expensive machinery.

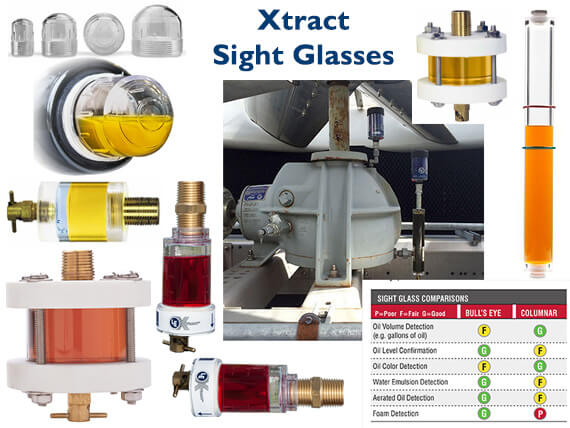

If you can't see it, how can you predict imminent machine failure? The foundation of any successful lubricant reliability program is laid with a comprehensive condition monitoring program. A combination of regular fluid analysis combined with additional monitoring tools including sight glasses, desiccant breathers and specialized monitoring equipment like Fluitec's Ruler can bring those otherwise invisible particulates into stark focus, arming you with the information you need to keep lubricants clean, cool and dry and your expensive equipment up and running.

With consistent, accurate monitoring of the condition of your oil – whether in an engine, gearbox, circulating system or mainline power generation turbine – implementation of a condition monitoring program will help you improve your bottom line with less lubricant to purchase, fewer parts to keep in inventory, less used lubricant to dispose of, less labor required for repairs and signifcantly reduce equipment downtime.

Fluitec

Measure. Consult. Treat.

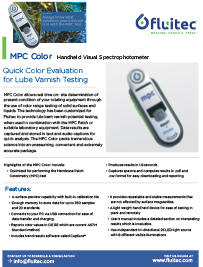

MPC

The Membrane Patch Colorimetry (MPC™) test is a quick, cost-effective way of assessing your oil's varnish potential.

The MPC Color instrument allows real time on-site determination of the condition of your lubricant. Data results are captured and stored in text and audio captions for quick analysis. The MPC Color packs tremendous science into a convenient and extremely accurate package.

Ruler V

The RULER® V™ provides the full picture of a fluid's antioxidant health - it's a window into the health of your lubricant. This technology is a critical part of an effective condition monitoring program.PRESENTATIONS & ARTICLES

Here is a small portion of our Case Studies, Articles, White Papers, Presentations and more. Are you curious about how things work? If so, then Click to View More!

-

Lube Tech Presentation

Marine/Shipping Applications -

ME - july/aug 2010

Emerging Problem of lubricant Varnish -

Baldor Motor Maintenance

MSSM0274AR/9731AV - Maintenance Manual -

Reprint: Global Cement Mag. oct 2007

Motor Bearings - ABB Switzerland -

TLT: Best Practices jan. 2010

Managing Lubricant Degradation -

UpTime: june/july 11

Automatic Lubrication Systems - Don't Work!?!