- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

GREASE PUMPS AND PUMP PACKAGES

Lubrication Technologies offers a full range of manual, air operated and electric grease pumps to handle fluid transfer or dispensing application needs considering logistic requirements, number and location of application points, and the characteristics of the fluid being transferred or dispensed.

We are able to meet many custom requirements in the heavy equipment, industrial, manufacturing industries, automotive and railroad, windmill turbines and construction. Shop online or contact our team of experts at Lubrication Technologies, Inc. (413) 788-5823 to order.

Choose from our selection of grease pumps, click on the photos below for more info

YAMADA KPL-24 Electric Lubricator 24 Volt DC electric connection, 4000 psi max discharge pressure typically used on excavators for a 5 gallon (35lb) pail of grease.

Windmill Package 110 Volt AC High Pressure, 4kpsi pump, digital read-out grease meter, control valve, high pressure hose supplied

Train Switch Package 4000 psi max high pressure, powered by 24-volt DC operation, engineered specifically for 5 gallon grease pail. Operates on mobile or stationary mining or construction equipment as it has a vibration resistance of 4G for all ground equipment.

Electric Grease Package 3500psi max high pressure. Metering: 300 cc / min (Motor 24 V DC) 150 cc / min (three-phase/single-phase). Designed to lubricate heavy duty and large machinery on up to 55-66 gallon drum.

HYDRA Hydraulic Pump 3500psi max high pressure. Metering: Adjustable from 120 to 400 cc / min. Transmission ratio: 10:1 with inlet pressure from 20 to 25 bar and Flow rate 10-18 l/1’ OR 11:1 with inlet pressure from 26 to 32 bar and Flow rate 18-28 l/1’. Designed to lubricate heavy duty and large machinery on up to 55-66 gallon drum.

GTP for manually refilling lubrication system pump reservoirs from 5 gallon pail using camlock adaptors or quick disconnect. Our GTP is the best choice for high volume / low pressure grease transfer, especially in remote or on-the-job applications.

Pressure Regulator W/Filter, Lubricator, Gauge To optimize the long life of the pneumatic equipment, we suggest using air without condensation, lubricated and at an adequate pressure. Inlet – outlet connection F 1/4” | Regulation 0+8 bar | Flow rate 1100 NI/min | Filtration 20 microns

Wheeled Air-Operated Grease Pump Set For 5 Gallon Pail Suitable for filling manual grease pumps. Includes Grease Pump; 2-Wheels Trolley; Lid; Follower Plate, 1/4" hose 4.0 m lenth, Grease Gun with Swiveling Joint

HP Wheeled Air-Operated Grease Pump Set For 16 Gallon Drums Includes Grease Pump =60:1; 2-pneumatic Wheels Trolley; Lid; Follower Plate, 1/4" hose 4.0 m lenth, Grease Gun with Swiveling Joint

Wheeled Air-Operated Grease Pump Set For 120 lb Drums Includes Grease Pump R=60:1; 2-pneumatic Wheels Trolley; Lid; Follower Plate, 1/2" hose 4.0 m lenth

120 lb. Drum Air-Operated Wheeled Greasing Pump Includes Grease Pump R=60:1; 2-pneumatic Wheels Trolley; Lid; Follower Plate, 1/2" hose 4.0 m lenth

35 lb. Drum (5 Gallon Pail) Wheeled Air-Operated Grease Sprayer Kit Includes Grease Pump R=60:1; 2-pneumatic Wheels Trolley; Lid; Follower Plate, 1/2" hose 4.0 m lenth

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

HEAVY EQUIPMENT PUMPS

Electric & Hydraulic Grease Pumps for Lubrication Systems

Sets up easily and fits directly onto a 5-gallon grease pail (a 16-gallon version is also available). It works with a hose reel and hand grease gun, and can be used stand-alone or with a centralized lubrication system.

The unit’s metal follower plate features Buna N wiping seals rather than being a solid piece of Buna N fastened to a coupling. The follower plate works in straight or tapered pails, and ensures the complete removal of grease from a container.

The KPL-24 High Pressure Electric Grease Pump has the ability to operate on just about any kind of mobile or stationary mining or construction equipment as it has a vibration resistance of 4G. Its maximum discharge pressure of 4,061 psi is one of the industry’s highest. Discharge volume is 80 to 120 grams/min in continuous operation and 70 to 80 grams/min in 30-minute periods. Operating temperatures range from 14 to 104°F.

Please call to order (413) 788-5823

Heavy Equipment Electric Pump Package

Elektra Electric Pump for Grease/Oil Lubrication Systems

High performance electric pump for Lubrication systems available in various motor sizes and components

The ILC Maximeter system has been designed to lubricate heavy duty and large machinery.The system consists of an Electric pump (ELEKTRA) which supplies the lubricant to a Single-line system equipped with CX, CM or CL valves. Each metering device supplies a single point and we can adjust its flow rate with precision.

The volumetric grease system distributes oils and greases up to NLGI 2 consistency to lubricate friction points in mining machines or glass industry. The system can have a large number of valves and provide an adjustable amount of lubricant for each point. The system is easy to install.

The ELEKTRA electric pumps have a standard configuration that has a 24 V DC motor. It is possible to supply single-phase motors 115 VAC, 230 VAC 50/60 Hz.

Please call to order (413) 788-5823

ELEKTRA Electric Pump for Grease/Oil Lubrication Systems

HYDRA Hydraulic Pump for Grease/Oil Lubrication Systems

High performance hydraulic pump for Lubrication systems available in various motor sizes and components

The ILC Maximeter Hydra system is designed to lubricate heavy duty and large machinery. The system consists of a Hydraulic pump (HYDRA) which supplies the lubricant to a Single-line system equipped with CX, CM or CL valves. Each metering device supplies a single point and we can adjust its flow rate with precision.

The volumetric grease system distributes oils and greases up to NLGI 2 consistency to lubricate friction points in mining machines or glass industry. The system can have a large number of valves and provide an adjustable amount of lubricant for each point. The system is easy to install.

Suitable for work in difficult conditions, particular environments and temperatures below or above the standard.

It is made entirely of steel with anti-corrosion plating to withstand harsh environments, and is mechanically operated (does not require electricity).

The 27 Kg and 41 Kg pumps are supplied with ILC tank of respective capacity. Whereas, the 180 kg pump is designed for installation in standard 180 kg grease drums with 2” F perforated cover.

The Overload prevention system is designed to improve the safety of workers. It helps prevent leaks that can cause slips and falls and reduce fire hazards. Compatible with any HYDRA grease tank, this product is easy to install, simple to use and reduces the labor work required to fill the tank, freeing personnel for other tasks.

Please call to order (413) 788-5823

HYDRA Hydraulic Pump for Grease/Oil Lubrication Systems

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

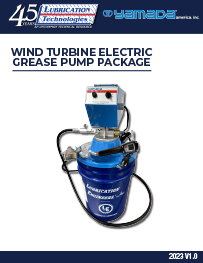

WIND TURBINE ELECTRIC GREASE PUMP PACKAGE

Lubrication Systems For Wind Turbines

Lubrication plays a crucial role in the overall maintenance of a wind turbine system. A premature failure of a bearing or gear can cost around $100,000, and that's not including downtime. Precision lubrication of critical bearings in the powertrain demands measured volumes of lubricant which many OEM's call out.

Using our Wind Turbine Electric Grease Pump Package allows technicians to grease bearings with a 110VAC high pressure (4kpsi) pump and record the precise amount of lubricant in grams that are delivered to each bearing.

COMPONENTS INCLUDED

- 110 Volt AC High Pressure Grease Pump

- Digital Read-Out Grease Meter

- Triple-swiveling joing, rigid end + 4 jaws coupling

- Control Valve

- 34' of high pressure hose supplied

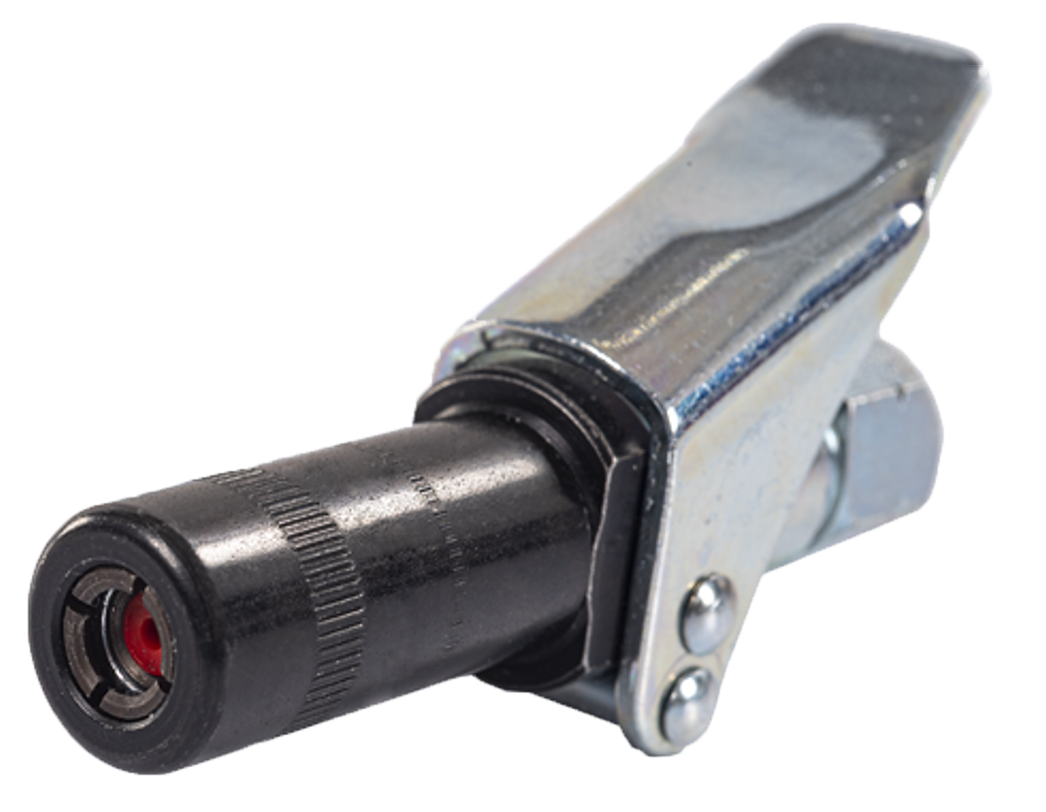

- Quick Coupler Meclube-Lock

- Bucket Sling (200 lb weight limit)

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

RAILROAD TRAIN SWITCH GREASE PACKAGE

One of the most important functions for which lubrication of railway tracks is important is the minimization of friction between the wheel flange and rail interface.

Lubrication is extremely important in the curves in the railway tracks, where side cutting of rails often occurs. If the rail tracks are unlubricated, the longevity of the rails will suffer, and they will need to be replaced frequently. Regular rail lubrication increases the longevity of these rails.

The KPL-24 High Pressure Electric Grease Pump has the ability to operate on just about any kind of mobile or stationary mining or construction equipment as it has a vibration resistance of 4G for all ground equipment.

FEATURES

- High discharge pressure - 4000 psi max

- The KPL-24 is powered by 24-volt DC operation

- Includes 50 foot 3/8" heavy duty hose reel with control valve

- Custom made heavy-duty hold down

- Pumps may be used in conjunction with a divider valve and a timer for automatic lubrication

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

HAND-OPERATED GREASE TRANSFER PUMP

Ideal for refilling Automatic Lubrication System reservoirs when no air or power is available at remote or on-the-job applications. The grease transfer pump is connected to ALS reservoirs using camlock or quick disconnect style adaptors. The manual GTP package utilizes a spring between the top lid and follower plate to maintain down pressure on the follower which assists in completely emptying the pail of lubricant. Complete package includes height adjustable lid and pump assembly which is compatible with all 35 lb. (5 gallon) type pails of lubricant, follower plate, 3-meter hose assembly and choice of cam lock or ¼” ISO B type quick disconnect connections. Pump side mating connections sold separately.

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 LB. (5 GALLON PAIL) AIR-OPERATED GREASE TRANSFER PUMP

Ideal for refilling automatic lubrication system reservoirs when shop air is available. The grease transfer pump is connected to ALS reservoirs using camlock or quick disconnect style adaptors. The GTP package utilizes a 14:1 air operated grease pump which delivers a maximum flow rate up to 4.4 lbs. per minute which fills lubrication system reservoirs quickly in a matter of minutes.

Complete package includes height adjustable lid and pump assembly which is compatible with all 35 lb. (5 gallon) type pails of lubricant, follower plate, two wheeled dolly, 4-meter hose assembly with ½” flow control ball valve. Pump side mating connections sold separately.

KIT INCLUDES

- Air-operated grease pump R=14:1

- Trolley with 2 pneumatic wheels

- Lid Ø 320 mm

- Follower plate Ø 310 mm

- Rubber hoses kit 1SC 1/2” Hose - 4.0 m length

- Ball Valve F-F 1/2"

- Steel znt Nipple M 1/2" BSP-M 1/4

- Quick Coupler F 1/4"

- Quick Coupler M 1/4"

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

120 LB. DRUM AIR-OPERATED GREASE TRANSFER PUMP

Ideal for refilling automatic lubrication system reservoirs when shop air is available. The grease transfer pump is connected to ALS reservoirs using camlock or quick disconnect style adaptors. The GTP package utilizes a 14:1 air operated grease pump which delivers a maximum flow rate up to 4.4 lbs. per minute which fills lubrication system reservoirs quickly in a matter of minutes.

Complete package includes height adjustable lid and pump assembly which is compatible with all 120 lb. type drums of lubricant, follower plate, two wheeled dolly, 4-meter hose assembly with ½” flow control ball valve. Pump side mating connections sold separately.

KIT INCLUDES

- Air-operated grease pump R=14:1

- Pressure regulator with connections

- Trolley with 2 pneumatic wheels

- Lid Ø 420 mm

- Follower plate Ø 400 mm

- 1SC 1/2” Hose - Length 4.0 M

- Ball Valve F-F 1/2"

- Steel ZNT Nipple M 1/2" BSP-M 1/4" BSP

- Quick Coupler F 1/4"

- Quick Coupler M 1/4"

- Air Filter/ Pressure Regulator/ Water Separator/ Lubricator Set

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

120 LB. DRUM AIR-OPERATED GREASING PUMP

Ideal for manual greasing tasks related to rotating assets in industrial environments. The air operated grease pump package utilizes a 60:1 air operated grease pump which delivers 56 oz. per minute.

Complete package includes height adjustable lid and pump assembly which is compatible with all 120 lb. type drums of lubricant, follower plate, four wheeled dolly with rear swivel casters, 4-meter hose assembly with lever operated grease control valve and hose swivel. Grease control valve includes zerk coupler and 15” flexible whip hose.

KIT INCLUDES

- Air-operated grease pump R=60:1

- Trolley with 4 pneumatic wheels

- Lid Ø 420 mm

- Follower plate Ø 400 mm

- 2SC 1/4” Hose - Length 4.0 M

- Grease Gun with Swivelling Joint

- Nozzles kit for grease spray gun HPS 1.9

- Air Filter/ Pressure Regulator/ Water Separator/ Lubricator Set

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

120 LB. DRUM AIR-OPERATED GREASING PUMP

Ideal for manual greasing tasks related to rotating assets in industrial environments. The air operated grease pump package utilizes a 60:1 air operated grease pump which delivers 56 oz. per minute.

Complete package includes height adjustable lid and pump assembly which is compatible with all 120 lb. type drums of lubricant, follower plate, four wheeled dolly with rear swivel casters, 4-meter hose assembly with lever operated grease control valve and hose swivel. Grease control valve includes zerk coupler and 15” flexible whip hose.

KIT INCLUDES

- Air-operated grease pump R=60:1

- Trolley with 2 pneumatic wheels

- Lid Ø 395 mm

- Follower plate Ø 370 mm

- 2SC 1/4” Hose - Length 4.0 M

- Grease Gun with Swivelling Joint

- Air Filter/ Pressure Regulator/ Water Separator/ Lubricator Set

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 LB. (5 GALLON PAIL) AIR-OPERATED GREASING PUMP

Ideal for manual greasing tasks related to trucks, trailers, buses, cranes, fork lifts, wheel loaders, excavators and any heavy equipment that requires lubrication through zerk fittings. The air operated grease pump package utilizes a 60:1 air operated grease pump which delivers 56 oz. per minute.

Complete package includes height adjustable lid and pump assembly which is compatible with all 35 lb. type pails of lubricant, follower plate, two wheeled dolly, 4-meter hose assembly with lever operated grease control valve and hose swivel. Grease control valve includes zerk coupler and 15” flexible whip hose.

KIT INCLUDES

- Air-operated grease pump R=60:1

- Trolley with 2 pneumatic wheels

- Lid Ø 320 mm

- Follower plate Ø 310 mm

- 2SC 1/4” Hose - Length 4.0 M

- Grease Gun with Swivelling Joint

- Air Filter/ Pressure Regulator/ Water Separator/ Lubricator Set

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallons Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallons Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 LB. (5 GALLON PAIL) AIR-OPERATED WHEELED GREASE SPRAY KIT

The grease spray kit helps personnel apply lubricant to large sliding surfaces quickly and uniformly. It is highly effective in ensuring that the lubricant is evenly distributed, making it ideal for use in a variety of industries. These industries include the assembly of waste compaction containers, industrial shears, telescoping boom cranes, and any other place where boundary lubrication is necessary.

The grease spray kit is a reliable and efficient solution that can help improve the performance and lifespan of equipment by reducing wear and tear. Using this kit can save time and increase productivity, making it an essential tool for any organization looking to streamline its lubrication process.

KIT INCLUDES

- Air-operated grease pump R=60:1

- Pressure regulator with connections

- Trolley with 2 pneumatic wheels

- Lid Ø 320 mm

- Follower plate Ø 310 mm

- Rubber hoses kit 2SC 1/4”+R6 5/16”with protection 15.0 m

- Grease spray gun F/160 SP HPS 2.2

- Nozzles kit for grease spray gun HPS 1.9

- Air Filter/ Pressure Regulator/ Water Separator/ Lubricator Set

Heavy Equipment Grease Pump Package | Wind Turbine Grease Pump Package | Train Switch Grease Pump Package | Hand-Operated Grease Transfer Pump

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

35 lb. (5 Gallon Pail) Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Grease Transfer Pump | 120 lb. Drum Air-Operated Greasing Pump120 lb. Drum Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Air-Operated Greasing Pump | 35 lb. (5 Gallon Pail) Wheeled Grease Spray Kit

120 lb. Drum Wheeled Grease Spray Kit

120 LB. DRUM AIR-OPERATED WHEELED GREASE SPRAY KIT

The grease spray kit helps personnel apply lubricant to large sliding surfaces quickly and uniformly. It is highly effective in ensuring that the lubricant is evenly distributed, making it ideal for use in a variety of industries. These industries include the assembly of waste compaction containers, industrial shears, telescoping boom cranes, and any other place where boundary lubrication is necessary.

The grease spray kit is a reliable and efficient solution that can help improve the performance and lifespan of equipment by reducing wear and tear. Using this kit can save time and increase productivity, making it an essential tool for any organization looking to streamline its lubrication process.

KIT INCLUDES

- Air-operated grease pump R=60:1

- Pressure regulator with connections

- Trolley with 2 pneumatic wheels

- Lid Ø 420 mm

- Follower plate Ø 400 mm

- Rubber hoses kit 2SC 1/4”+R6 5/16”with protection 15.0 m

- Grease spray gun F/160 SP HPS 2.2

- Nozzles kit for grease spray gun HPS 1.9

- Air Filter/ Pressure Regulator/ Water Separator/ Lubricator Set