- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

LE GREASES

Lubrication Technologies, Inc. has been an independent manufacturer's representative of Lubrication Engineers, Inc. for over 45 years. LE’s line of high-performance lubricants – manufactured and made of highly refined base oils and proprietary additives – far exceed the performance of conventional lubricants in a wide variety of industrial and automotive applications. LE greases offer benefits such as reduced wear, reduced operating temperatures, longer equipment life, enhanced performance, increased efficiency, increased uptime, lower grease consumption, longer service intervals and reduced maintenance. Call our consultants at Lubrication Technologies (413) 788-5823 for more information on LE Products. We will grant a 5% discount, only available to new LE customers.

Lubrication Technologies, Inc. has been an independent manufacturer's representative of Lubrication Engineers, Inc. for over 45 years. LE’s line of high-performance lubricants – manufactured and made of highly refined base oils and proprietary additives – far exceed the performance of conventional lubricants in a wide variety of industrial and automotive applications. LE greases offer benefits such as reduced wear, reduced operating temperatures, longer equipment life, enhanced performance, increased efficiency, increased uptime, lower grease consumption, longer service intervals and reduced maintenance. Call our consultants at Lubrication Technologies (413) 788-5823 for more information on LE Products. We will grant a 5% discount, only available to new LE customers.

GENERAL PURPOSE GREASES

Versatile Grease Offers Long-Lasting Protection

General Purpose Greases

General Purpose Greases

General purpose grease protects equipment from heat, moisture, and heavy loads. Formula imparts high dropping point, inherent extreme pressure characteristics, mechanical stability, low oil bleed, and water resistance. Calcium sulfonate thickener prevents rust and corrosion, while Monolec® protects against metal-to-metal contact, resists oxidation, and helps grease maintain consistency.

The general purpose greases that LE offers is a versatile lubricant for use in severe conditions such as high temperatures, heavy loads and water. It provides long-lasting reliable protection and is the right solution for many equipment uses and in a wide variety of industries, especially those in which moisture problems are caused by high humidity, elevated operating temperatures, and severe environmental contamination.

To learn more about each of the lubricants, click on the photos below

1232 Almatek® increases uptime, reduces maintenance costs and lowers lubrication costs

1274-1275 Almaplex® extremely versatile, minimizing inventory requirements and misapplication because it works in many different applications

1488 - 1487 ALMAMOLY™ for use in severe conditions such as high temperatures, heavy loads and water

1498 - 1499 MONOCAL® General Purpose for use in severe conditions such as high temperatures, heavy loads and water

3750 - 3751 - 3752 ALMAGARD® cool-running, long-lasting, water-resistant performance

4622 Monolec® Multiplex® Lubricant a highly versatile, long-life, lithium-complex-thickened grease designed for extreme pressure (EP) performance in a variety of farm, fleet, industrial and marine applications

4701 Monolec® Industrial Designed especially for use in centralized lubrication systems, ensures consistent pumpability for reliable equipment protection in a variety of industrial applications

EXTREME PRESSURE GREASES

Versatile Grease Offers Long-Lasting Protection

Extreme Pressure Greases

Extreme Pressure Greases

Wear prevention and the ability to carry a load are important characteristics of industrial lubricants. Both of the evaluated lubricants contain heavy ISO 460 viscosity grade synthetic base fluids. This helps when the greases operate in a hydrodynamic regime, However, functionality of the lubricants under elastohydrodynamic (EHD) and boundary lubrication regimes is also important. EHD and boundary lubrication are often more dependant upon the chemicals used as extreme pressure additives in a lubricant rather than a function of the thickener system.

LE’s greases are formulated for a variety of industries and applications to provide protection for components and parts such as bearings, bucket pins, bushings, cables, cams, chains, chassis and open gears. LE greases offer varying benefits such as reduced wear, reduced operating temperatures, longer equipment life, enhanced performance, increased efficiency, increased uptime, lower grease consumption, longer service intervals and reduced maintenance.

Monolec® Multiplex Lubricant is a highly versatile, long-life, lithium complex thickened grease designed for extreme pressure (EP) performance in a variety of farm, fleet, industrial and marine applications. It provides dependable performance in a broad operating temperature range in chassis, wheel bearings and other critical grease points. It meets the requirements of NLGI’s GC-LB grease specification.

Typical Applications:

Chassis points, front-axle arrangements, U-joints and wheel bearings in equipment, such as debarkers, ditching machines, dump trucks, forklifts, front-end loaders, and vehicle fleets; plain and anti-friction bearings in a variety of machinery, including conveyors, electric motors and fans; pillowblock bearings

To learn more about each of the lubricants, click on the photos below

1274-1275 Almaplex® extremely versatile, minimizing inventory requirements and misapplication because it works in many different applications

1295-1299 Almaplex Ultra-Syn Engineered to provide optimum performance capabilities under extreme equipment operating conditions. Provides excellent performance in the presence of water. Exhibits low-temperature pumpability down to 30°F (-1°C), as well as superior high-temperature functionality.

1488 - 1487 ALMAMOLY™ for use in severe conditions such as high temperatures, heavy loads and water

1498 - 1499 MONOCAL® General Purpose for use in severe conditions such as high temperatures, heavy loads and water

3750 - 3751 - 3752 ALMAGARD® cool-running, long-lasting, water-resistant performance

4622 Monolec® Multiplex® Lubricant a highly versatile, long-life, lithium-complex-thickened grease designed for extreme pressure (EP) performance in a variety of farm, fleet, industrial and marine applications

4701 Monolec® Industrial Designed especially for use in centralized lubrication systems, ensures consistent pumpability for reliable equipment protection in a variety of industrial applications

HIGH TEMPERATURE GREASES

Long-Lasting, Non-Melting Grease Provides Constant Protection for High-Temperature Bearing Applications

‘High’ is relative when characterizing temperature conditions. Bearings running in a steel mill roll-out table application may be exposed to process temperatures of several hundreds of degrees, and may experience sustained temperatures of 250ºF to 300ºF (120ºC to ±150ºC).

‘High’ is relative when characterizing temperature conditions. Bearings running in a steel mill roll-out table application may be exposed to process temperatures of several hundreds of degrees, and may experience sustained temperatures of 250ºF to 300ºF (120ºC to ±150ºC).

Automotive assemblers hang painted metal parts on long conveyors and weave them through large drying ovens to dry painted metal surfaces. Operating temperatures for these gas-fired ovens are maintained around 400ºF (205ºC).

In these two cases, the selection criteria differ appreciably. In addition to heat resistance, the grease to be used in a hot steel mill application may require exceptional load-carrying capability, oxidation stability, mechanical stability, water wash resistance and good pumpability, and at a price suitable for large-volume consumption. With all of the important factors to consider, it is useful to have a grease selection strategy.

The selection must include consideration of oil type and viscosity, oil viscosity index, thickener type, stability of the composition formed by the oil and the thickener), additive composition and properties, ambient temperature, operating temperature, atmospheric contamination, loading, speed, relubrication intervals, etc.

With the variety of details to resolve, the selection of greases that must accommodate extreme temperature conditions poses some of the more challenging lubrication engineering decisions.

Given the variety of options, the potential for incompatibility problems and high prices for a given high-temperature product, the lubrication engineer must be selective and discriminating when sourcing products to meet high-temperature requirements.

Bearings operating in or near heat-generating equipment are subject to temperatures that cause ordinary greases to melt and run, leaving critical bearing surfaces unprotected. Almasol® High Temperature Lubricant is designed to withstand high temperatures, staying in place to provide constant lubrication. It also resists oxidation and vaporization. By ensuring longer lubrication intervals and fewer bearing failures, Almasol High Temperature Lubricant helps contribute to

increased production and a healthier bottom line.

To learn more about each of the lubricants, click on the photos below

1250 - 1251 Almasol® Long-Lasting, Nonmelting Grease Provides Constant Protection for High-Temperature Bearing Applications

1295-1299 Almaplex Ultra-Syn Engineered to provide optimum performance capabilities under extreme equipment operating conditions. Provides excellent performance in the presence of water. Exhibits low-temperature pumpability down to 30°F (-1°C), as well as superior high-temperature functionality.

1488 - 1487 ALMAMOLY™ for use in severe conditions such as high temperatures, heavy loads and water

1498 - 1499 MONOCAL® General Purpose for use in severe conditions such as high temperatures, heavy loads and water

9102 Syntemp® Synthetic Lubricant WITHSTANDS HIGH TEMPERATURES, WON'T SLING OFF, IN A CONVENIENT AEROSOL CAN

9901 Almasol Syntemp Lubricant High temperature lubricant made from a very heavy synthetic fluid and a nonmelting base. It is specially formulated to provide exceptional protection at temperatures at which petroleum oils would completely oxidize or carbonize. Contains Almasol, LE's exclusive wear-reducing additive.

FOOD GRADE OIL & GREASES

Food machinery lubricants key to plant success

When it comes to food, beverage and pharmaceutical applications, Lubrication Engineers food grade oil and food grade grease can play a significant role in preventing costly damage brought on by severe operating conditions. Our high-performance food grade greases and oils are registered NSF H1 for incidental food contact, certified Kosher Pareve, and certified Halal by IFANCA – making them suitable for use in food manufacturing plants.

When it comes to food, beverage and pharmaceutical applications, Lubrication Engineers food grade oil and food grade grease can play a significant role in preventing costly damage brought on by severe operating conditions. Our high-performance food grade greases and oils are registered NSF H1 for incidental food contact, certified Kosher Pareve, and certified Halal by IFANCA – making them suitable for use in food manufacturing plants.

Regardless of load, temperature, environment and speed, LE has a suitable food machinery lubricant solution for your facility. Some of LE’s food machinery lubricants are additive-free USP-grade white mineral oils, while others contain our exclusive additive Quinplex that imparts various qualities to our food machinery lubricants, including impact resistance, wear reduction, and increased oil film strength.

Our formulation of food grade oils and greases have been used in food manufacturing operations for years to provide dependable reliable operation. Typical applications where our customers have used LE’s food grade lubricants include blenders, bottle washers, cams, conveyors, gearboxes, slides, conveyer chains, cookers, bottling machines, packaging equipment, valves, hydraulics, canning machines, bushings and more. We have numerous testimonials showcasing how we have helped customers with their lubrication reliability, including critical applications and equipment.

Food machinery lubricants are key to your plants success.

A high-performance food grade oil or grease can go a long way toward combating severe operating conditions and preventing the toll these conditions can take on expensive machinery.

Food processing equipment requires tough, durable lubricants that must withstand conditions such as washdowns, high oven temperatures and areas susceptible to high contamination. Our H1 and H2 lubricants include solutions for heat, cold, moisture, rust and oxidation, wear, foaming, staining, odor, frequent visual inspections, and much more.

To learn more about each of the H1 lubricants, click on the photos below

LE Quinplex 4022-4023-4024-4025 Food grade machinery lubricant - Semi-Synthetic Grease Protects Against Moisture & Other Harsh Conditions at Food Manufacturing Plants. Exhibits long-lasting mechanical stability, does not change consistency after being worked thousands of times.

4070-4071-4072 Quincal™ Syn Food Grade Grease Formulated for use in food processing applications, superior mechanical stability, low oil bleed, tackiness and water resistance. Especially effective on bearings operating in a warm, moist environment or in operations where a lot of water is needed to keep equipment cool.

H1 Quinplex Synthetic Food Grade Oils 4032, 4046, 4068 Certified lubricants designed to use in food processing and other sensitive environments where superior anti-wear, rust- and oxidation-resistant properties are required. Featuring 100% synthetic base oil, H1 Quinplex 4032, 4046 and 4068 have excellent load-carrying abilities, can be used in low-temperature applications, and contain Quinplex®, LE’s proprietary impact-resistant additive.

H1 Ovenworx® Syn Chain Lubricant 4061 Formulated specifically to combat the demanding conditions present with oven chain applications. In addition, it is approved for incidental food contact and contains no artificial dyes, making it a good choice for food manufacturing plants.

H1 Quinplex High Temperature Lubricant 4051 Designed to withstand high temperatures, staying in place to provide constant lubrication. It also resists oxidation and vaporization, and it repels water. NSF H1 certified, it is suitable for use in food processing and other sensitive environments.

H1 Quinplex High Temperature Lubricant 4051 Designed to use in food processing and other sensitive environments where superior anti-wear, rust- and oxidation-resistant properties are required.

NSF H1 and USDA H2 food machinery lubricants

A variety of food, beverage and pharmaceutical plant applications require the use of both H1 and H2 lubricants. NSF H1-certified lubricants have been cleared for use in USDA-inspected food processing plants, and can be used where incidental food contact may occur. The Orthodox Union also certifies all LE H1 lubricants – except for H1 Machine Oil – Kosher Pareve. H2 lubricants meet USDA H2 criteria for nonfood contact areas of food processing plants. Most LE lubricants meet USDA H2 criteria.An H1 lubricant can serve as a protective anti-rust film, a release agent on gaskets or seals of tank closures, and as grease for machine parts and equipment. Uses for H2 lubricants include any nonfood contact areas of a food or beverage plant. These applications are usually below the production line and include oven chains, air compressors, oil circulating systems, enclosed gears, industrial turbines, hydraulics and oiled bearings.

To learn more about each of the USDA H2 lubricants, click on the photos below

Recommended for Nonfood Contact Areas

H2 lubricants meet USDA H2 criteria for nonfood contact areas of food processing plants. These are lubricant applications with no possibility of food contact and are usually below the production line. Most LE lubricants meet USDA H2 criteria. See pages 3 and 4 of this brochure for those USDA H2 lubricants used most frequently by LE’s food and beverage customers.

1250 - 1251 Almasol® Long-Lasting, Nonmelting Grease Provides Constant Protection for High-Temperature Bearing Applications

1299 - 1298 - 1297 - 1295 Almaplex® Ultra-Syn Heavy-Duty Grease Performs in Extreme Conditions

1488 - 1487 ALMAMOLY™ for use in severe conditions such as high temperatures, heavy loads and water

1498 - 1499 MONOCAL® General Purpose for use in severe conditions such as high temperatures, heavy loads and water

9102 Syntemp® Synthetic Lubricant WITHSTANDS HIGH TEMPERATURES, WON'T SLING OFF, IN A CONVENIENT AEROSOL CAN

9901 Almasol Syntemp Lubricant High temperature lubricant made from a very heavy synthetic fluid and a nonmelting base. It is specially formulated to provide exceptional protection at temperatures at which petroleum oils would completely oxidize or carbonize. Contains Almasol, LE's exclusive wear-reducing additive.

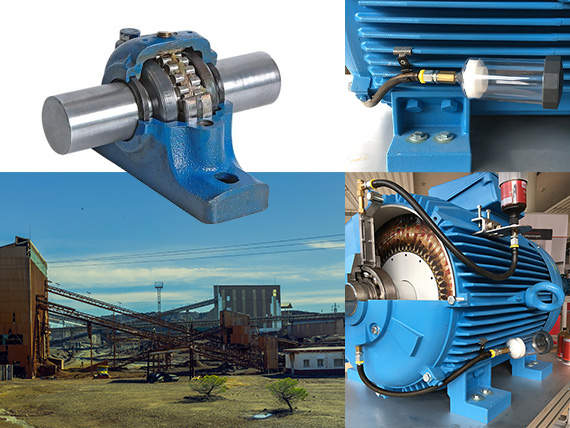

ELECTRIC MOTOR GREASE

Versatile Grease Offers Long-Lasting Protection

Electric Motor Greases

Electric Motor Greases

Incorrect Grease Selection

Selecting the right grease for electric motor applications can make all the difference in the protection and performance of bearings. Electric motors require lubricants with specific characteristics. Use of the wrong grease often leads to early electric motor failures.

LE Solution

The grease consistency preferred for electric motors is normally NLGI 2 or 3, with a base oil viscosity of 100-150 cSt @ 40°C. Other characteristics to look for include good channeling characteristics, low oil bleed, oxidation resistance, anti-wear additives, and mechanical stability. A polyurea thickener system is preferred for most electric motor applications, but grease with an aluminum complex, lithium complex or calcium sulfonate thickener are also good options.

Most electric motors are designed with grease-lubricated, antifriction, rolling-element bearings. Grease is the lifeblood of these bearings because it provides an oil film that prevents the harsh metal-to-metal contact between the rotating element and races. Bearing troubles account for 50 to 65 percent of all electric motor failures, and poor lubrication practices account for most of these bearing troubles. Proper maintenance procedures, planning and the use of the correct lubricant can increase productivity by reducing these bearing troubles and motor failures.

Incorrect Grease Application

Incorrect Grease Application

Common problems include overgreasing, undergreasing, and not greasing at all – all of which can lead to premature electric motor failures. Additionally, operators often have to manually grease in hard-to-reach or unsafe areas.

LE Solution

As an LE consultant we can help determine correct lubrication amounts and intervals, and then help you choose which Single Point Lubricator will work best in your application. These precision lubrication tools provide a closed loop system to keep out contaminants, and they take the guesswork out of maintenance by supplying the right amount of grease for the application at the right time 24/7. Suitable for indoor and outdoor applications, Single Point Lubricator decrease motor failures, reduce labor time and improve safety.

To learn more about each of the lubricants, click on the photos below

1274-1275 Almaplex® extremely versatile, minimizing inventory requirements and misapplication because it works in many different applications.

1282 Monolec Industrial Formulated with polyurea thickener and designed specifically for use in electric motor bearings, Monolec® Extend EM Grease offers superior mechanical stability for long service life.

1498 - 1499 MONOCAL® General Purpose for use in severe conditions such as high temperatures, heavy loads and water

4070-4071-4072 Quincal™ Syn Food Grade Grease Formulated for use in food processing applications, superior mechanical stability, low oil bleed, tackiness and water resistance. Especially effective on bearings operating in a warm, moist environment or in operations where a lot of water is needed to keep equipment cool.

4622 Monolec® Multiplex® Lubricant a highly versatile, long-life, lithium-complex-thickened grease designed for extreme pressure (EP) performance in a variety of farm, fleet, industrial and marine applications

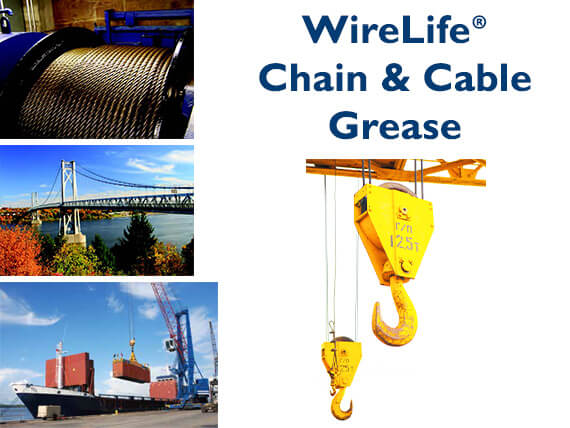

CHAIN & CABLE GREASES

Self-Healing Fluid Seals & Protects Surfaces

Chain & Cable Greases

Chain & Cable Greases

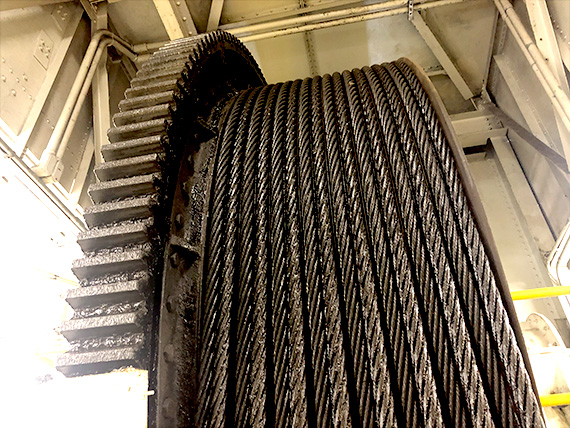

Wire rope forms an important part of many machines and structures. It is comprised of continuous wire strands wound around a central core. There are many kinds of wire rope designed for different applications. Most of them are steel wires made into strands wound with each other. The core can be made of steel, rope or even plastics.

Wire ropes (cables) are identified by several parameters including size, grade of steel used, whether or not it is preformed, by its lay, the number of strands and the number of wires in each strand.

Years of field experience have shown that wire rope life can be maximized by using the right lubricants combined with the right application method. Companies that have recognized the importance of proper wire rope lubrication and adopted best practices have gained a huge advantage by lengthening wire rope life, eliminating costly replacements and improving safety. Factors that influence wire rope life and performance include type of operation, care and environment. Two problems include wear and corrosion. Wear is accelerated by stress-loading; shock-loading; heavy, jerking loads; or rapid acceleration or deceleration (speed of the cable stopping and starting). Corrosion is caused by fumes, acids, salt brines, sulfur, gases, salt air, and humidity; and can be accelerated by elevated temperatures. The right type and quantity of lubricant will protect the wire rope from degradation, regardless of cause

To learn more about each of the lubricants, click on the photos below

2001 Monolec Wirelife has excellent corrosion resistance and high load carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with 2002 Wirelife Almasol Coating Lubricant, maximum protection and wear reduction is achieved.

2002 Almasol WireLife fluid wire rope lubricant that provides a tough outer coating to seal and protect against fretting corrosion, wear and rust - even under extreme load and moisture. It seals and protects better than any product available. When used in conjunction with 2001 Wirelife Monolec Penetrating Lubricant, maximum protection and wear reduction is achieved.

451 - 453 Almasol Wirelife Tacky Grease Resists Water, Protects Moving Parts and was designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation

3353 Earthwise Certified Environmentally Acceptable Lubricant (EAL), recommended for use in applications on or near waterways. It meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms.

H1 Ovenworx® Syn Chain Lubricant 4061 Formulated specifically to combat the demanding conditions present with oven chain applications. In addition, it is approved for incidental food contact and contains no artificial dyes, making it a good choice for food manufacturing plants.

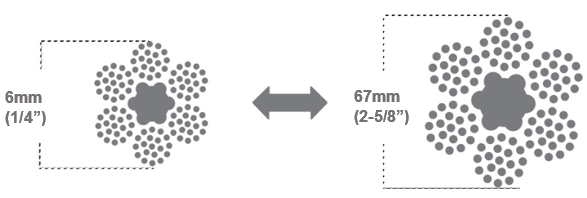

VIPER MKII WIRE ROPE LUBRICATORS

SUPERIOR PROTECTION OF WIRE ROPES - 6MM TO 67MM

SUPERIOR PROTECTION OF WIRE ROPES - 6MM TO 67MMProviding fast and effective cleaning and lubrication of wire ropes.

Clean and lubricate wire ropes quickly efficiently and safely with the Viper MKII series of Wire Rope Lubricators. The release of the Viper MkII provides the same excellent wire rope lubrication performance with the added benefit of a 32% lighter collar and custom built high flow grease pump. Watch the video to see the benefits of the new Viper MkII.

Fast and effective lubrication of wire ropes with a diameter between 6mm to 67mm. The Viper Mid MKII lubricates ropes at up to 2000mt/hour.

APPLICATIONS

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.

- Every gram of grease goes on the rope – no contamination

- Wharf Cranes

- Ship Cranes

- ROV Cables

- Mine Winders

- Mobile Cranes

- Oil & Gas Platforms

- Anchor Ropes

- Deck Winches

- Overhead Cranes

- Ship Loaders

INCREASE WIRE ROPE LIFE UP TO 300%

The Viper MKII Wire Rope Lubricator range provides fast and effective cleaning and lubricating of wire ropes. Wire ropes from 6mm (1/4” ) to 67mm (2-5/8”) in diameter can be automatically greased at speeds up to 2,000mt per hour.The Viper MKII with the new cast Aluminium collar is 32% lighter and combined with the unique inbuilt carry handles and shoulder strap enables single person wire rope lubrication. Ideal for use on all cranes, towing lines and mooring lines, the Viper MKII eliminates the HS&E risks associated with manual lubrication. Use of the Viper MKII provides improved wire rope lubrication by forcing wire rope lubricant under pressure into the wire rope.

Other lubricators just coat the surface of the ropes but the unique seal design of the Viper wire rope lubricator means the “wire dwell time” in the pressure chamber is up to 80% longer. This longer dwell time means greater lubricant penetration which leads to increased rope life and extended relubrication intervals.

WHY USE THE VIPER

CLEAN AND LUBRICATE WIRE ROPES QUICKLY, EFFICIENTLY AND SAFELY WITH THE VIPER MKII SERIES OF WIRE ROPE LUBRICATORS.

CLEAN AND LUBRICATE WIRE ROPES QUICKLY, EFFICIENTLY AND SAFELY WITH THE VIPER MKII SERIES OF WIRE ROPE LUBRICATORS.

- Eliminates manual greasing

- Single pass lubrication

- Stops corrosion, protects ropes

- Viper MKII - 8mm (5/16") to 67mm (2-5/8")

- Viper Maxi MKII: 50mm (2") to 165mm (6-1/2")

- Penetrative, displaces moisture from rope's core

- Safer, reduced lubricant usage, less leakage & mess

- Fast, efficient wire rope lubrication

- Reduces downtime, improves equipment availability Custom units available

HEALTH SAFETY ENVIRONMENT

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.- Every gram of grease goes on the rope – no contamination

- Does not leak meaning no mess

- No wasted lubricant

- Light weight allows for safe application

- There is no personal contact with the lubricant

- The rope is able to be lubricated from a safe distance

VIPER MID MKII EFFECTIVELY REMOVES GREASE DEPOSITS & PERFECTLY LUBRICATES WIRE ROPES

-

Fast and effective lubrication of wire ropes

Lubricating ropes at up to 2000mt/hour -

Provides grease penetration, moisture displacement

& total coverage by forcing lubricant into the core of the rope -

Developed with safety & the environment in mind

The rope is able to be lubricated from a safe distance & No wasted lubricant.

Common lubricant suffering points for the marine industry include:

Engines - Greases that are subject to heat can melt and run out of bearings. Greases that do not form a good seal can let in contaminants. LE has greases that are extremely tacky and nearly impervious to water washout, and can handle heavy loads with ease. We also offers automatic lubrication systems for making sure grease is applied in the right place at the right time in the right quantity.

Engine oil - If you are looking for longer oil life while still protecting your engine from the demands of the workload, LE can help you safely extend oil drain intervals with our superior, long-lasting engine oils and LEAP oil analysis.

Diesel fuel - Water can get into the fuel of diesel equipment kept outside, causing a loss of power. Injectors get dirty from the buildup of soot. In addition, environmental issues have led to the use of lower performance diesel fuel in on-road and off-road mobile equipment. LE has diesel fuel improvers that address these problems. They can clean up your fuel pumps, injectors and combustion chambers, thereby helping you regain fuel economy, reduce emissions and lower the overall cost per mile or hours of operation.

Wire rope - Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE's full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

Difficulties with maritime lubrication

Although ship building involves some unique processes, component manufacturing is not dissimilar to other manufacturing industries. The difficulty in marine lubrication comes with maintenance procedures. In such a busy industry most ships don’t get much time to rest, and maintenance is done mid-voyage, with machinery operating.

The equipment can be in hazardous locations and often exposed to the brutal forces of nature. Add violent rocking to the list and maintenance procedures can be hazardous.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

SYNTHETIC GREASE

Non-synthetic lubricants aren’t always the best lubricants for the job. In applications with extremely high or extremely low temperatures or very heavy loads, synthetic lubricants may overcome the challenges better than non-synthetic lubricants. For example, a synthetic gear oil would provide exceptional protection in heavily loaded gearboxes exposed to high and low temperature extremes. Another example is a synthetic engine oil or synthetic motor oil, which would provide better viscosity stability in extreme temperature conditions.

The performance advantages offered by synthetic oils and synthetic greases vary by product, but they include improved thermal stability, improved oxidation resistance, a high viscosity index, improved low-temperature properties, lower evaporation losses, reduced flammability and a lower tendency to form residues.

LE’s synthetic oil and synthetic grease varieties contain special additives that further enhance their performance. Depending on the particular lubricant and what LE formulated it to do, these additives include one or more of the following:

- Monolec® LE’s exclusive wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. Monolec® allows opposing surfaces to slide by one another, greatly reducing friction, heat and wear.

- Almasol® LE’s exclusive solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and extremely high temperatures. It is attracted to metal surfaces, forming a microscopic layer without building on itself or affecting clearances. Almasol® minimizes metal-to-metal contact and the resulting friction, heat and wear.

- Quinplex® LE’s exclusive impact-resistant additive helps to form a barrier against corrosion and enables outstanding water resistance, tackiness and enhanced mechanical stability.