- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

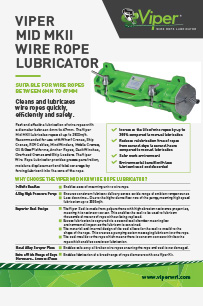

VIPER MKII WIRE ROPE LUBRICATORS

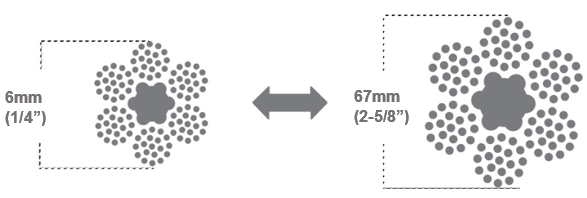

SUPERIOR PROTECTION OF WIRE ROPES - 6MM TO 67MM

SUPERIOR PROTECTION OF WIRE ROPES - 6MM TO 67MMProviding fast and effective cleaning and lubrication of wire ropes.

Clean and lubricate wire ropes quickly efficiently and safely with the Viper MKII series of Wire Rope Lubricators. The release of the Viper MkII provides the same excellent wire rope lubrication performance with the added benefit of a 32% lighter collar and custom built high flow grease pump. Watch the video to see the benefits of the new Viper MkII.

Fast and effective lubrication of wire ropes with a diameter between 6mm to 67mm. The Viper Mid MKII lubricates ropes at up to 2000mt/hour.

APPLICATIONS

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.

- Every gram of grease goes on the rope – no contamination

- Wharf Cranes

- Ship Cranes

- ROV Cables

- Mine Winders

- Mobile Cranes

- Oil & Gas Platforms

- Anchor Ropes

- Deck Winches

- Overhead Cranes

- Ship Loaders

INCREASE WIRE ROPE LIFE UP TO 300%

The Viper MKII Wire Rope Lubricator range provides fast and effective cleaning and lubricating of wire ropes. Wire ropes from 6mm (1/4” ) to 67mm (2-5/8”) in diameter can be automatically greased at speeds up to 2,000mt per hour.The Viper MKII with the new cast Aluminium collar is 32% lighter and combined with the unique inbuilt carry handles and shoulder strap enables single person wire rope lubrication. Ideal for use on all cranes, towing lines and mooring lines, the Viper MKII eliminates the HS&E risks associated with manual lubrication. Use of the Viper MKII provides improved wire rope lubrication by forcing wire rope lubricant under pressure into the wire rope.

Other lubricators just coat the surface of the ropes but the unique seal design of the Viper wire rope lubricator means the “wire dwell time” in the pressure chamber is up to 80% longer. This longer dwell time means greater lubricant penetration which leads to increased rope life and extended relubrication intervals.

WHY USE THE VIPER

CLEAN AND LUBRICATE WIRE ROPES QUICKLY, EFFICIENTLY AND SAFELY WITH THE VIPER MKII SERIES OF WIRE ROPE LUBRICATORS.

CLEAN AND LUBRICATE WIRE ROPES QUICKLY, EFFICIENTLY AND SAFELY WITH THE VIPER MKII SERIES OF WIRE ROPE LUBRICATORS.

- Eliminates manual greasing

- Single pass lubrication

- Stops corrosion, protects ropes

- Viper MKII - 8mm (5/16") to 67mm (2-5/8")

- Viper Maxi MKII: 50mm (2") to 165mm (6-1/2")

- Penetrative, displaces moisture from rope's core

- Safer, reduced lubricant usage, less leakage & mess

- Fast, efficient wire rope lubrication

- Reduces downtime, improves equipment availability Custom units available

HEALTH SAFETY ENVIRONMENT

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.- Every gram of grease goes on the rope – no contamination

- Does not leak meaning no mess

- No wasted lubricant

- Light weight allows for safe application

- There is no personal contact with the lubricant

- The rope is able to be lubricated from a safe distance

VIPER MID MKII EFFECTIVELY REMOVES GREASE DEPOSITS & PERFECTLY LUBRICATES WIRE ROPES

-

Fast and effective lubrication of wire ropes

Lubricating ropes at up to 2000mt/hour -

Provides grease penetration, moisture displacement

& total coverage by forcing lubricant into the core of the rope -

Developed with safety & the environment in mind

The rope is able to be lubricated from a safe distance & No wasted lubricant.

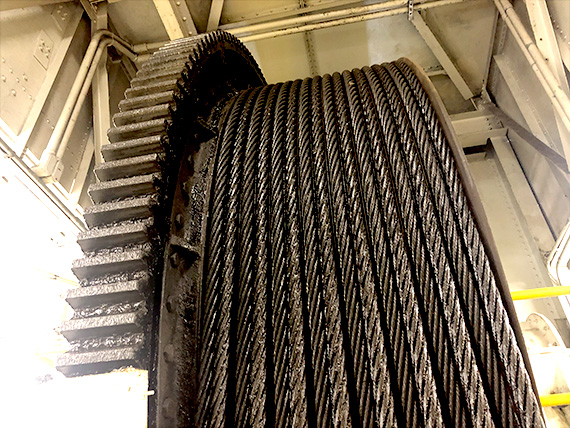

Wire rope

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE's full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

Difficulties with maritime lubrication

Although ship building involves some unique processes, component manufacturing is not dissimilar to other manufacturing industries. The difficulty in marine lubrication comes with maintenance procedures. In such a busy industry most ships don’t get much time to rest, and maintenance is done mid-voyage, with machinery operating.

The equipment can be in hazardous locations and often exposed to the brutal forces of nature. Add violent rocking to the list and maintenance procedures can be hazardous.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

CHAIN & CABLE GREASES

Self-Healing Fluid Seals & Protects Surfaces

Chain & Cable Greases

Chain & Cable Greases

Wire rope forms an important part of many machines and structures. It is comprised of continuous wire strands wound around a central core. There are many kinds of wire rope designed for different applications. Most of them are steel wires made into strands wound with each other. The core can be made of steel, rope or even plastics.

Wire ropes (cables) are identified by several parameters including size, grade of steel used, whether or not it is preformed, by its lay, the number of strands and the number of wires in each strand.

Years of field experience have shown that wire rope life can be maximized by using the right lubricants combined with the right application method. Companies that have recognized the importance of proper wire rope lubrication and adopted best practices have gained a huge advantage by lengthening wire rope life, eliminating costly replacements and improving safety. Factors that influence wire rope life and performance include type of operation, care and environment. Two problems include wear and corrosion. Wear is accelerated by stress-loading; shock-loading; heavy, jerking loads; or rapid acceleration or deceleration (speed of the cable stopping and starting). Corrosion is caused by fumes, acids, salt brines, sulfur, gases, salt air, and humidity; and can be accelerated by elevated temperatures. The right type and quantity of lubricant will protect the wire rope from degradation, regardless of cause

To learn more about each of the lubricants, click on the photos below

2001 Wirelife penetrates to the core of wire ropes, whether they are running or stationary.

2002 Almasol WireLife Self-Healing Fluid Seals & Protects Surfaces in addition to providing moderate penentration

451 - 453 Almasol Wirelife Tacky Grease Resists Water, Protects Moving Parts and was designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation

3353 Earthwise LE’s Earthwise™ is a certified Environmentally Acceptable Lubricant (EAL) and is specifically formulated to be earth friendly while still meeting the rigorous demands of industrial applications.